Minimize your losses due to unnecessarily bought material thanks to K2.

E-commerce

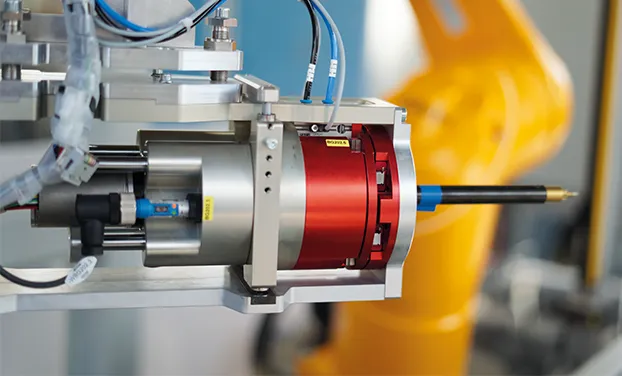

K2 ERP is currently deployed in the ELVAC group, including the subsidiary in Slovakia – ELVAC SK. The companies therefore have their data stored in one common database in K2. This simplifies the creation of internal documents between companies, easy sharing of workflow processes and simple creation of consolidated reports over the entire holding. In all companies, K2 ERP manages production, warehouse and evaluation of business opportunities. Thanks to the analysis of material availability in K2, the ELVAC company is able to plan production weeks in advance and at the same time offer customers the shortest possible realistic order delivery date.

Using K2 as a platform suitable for creating your own solutions.

Operation of three K2 e- shops.

Product progress tracking for merchants.

Support for multiple legislations in one K2 installation.

Automatic import of delivery dates from suppliers.

Production planning according to confirmed material delivery dates.

Without flexible K2 ERP tools, we cannot imagine production in today's volumes. Thanks to K2, we have reduced losses due to unnecessarily purchased parts and shortened delivery times, which caused us to lose customers in the past. We decided on K2 a few years ago, when we were dealing with the rapidly growing production of our own products, and we have never regretted this choice.